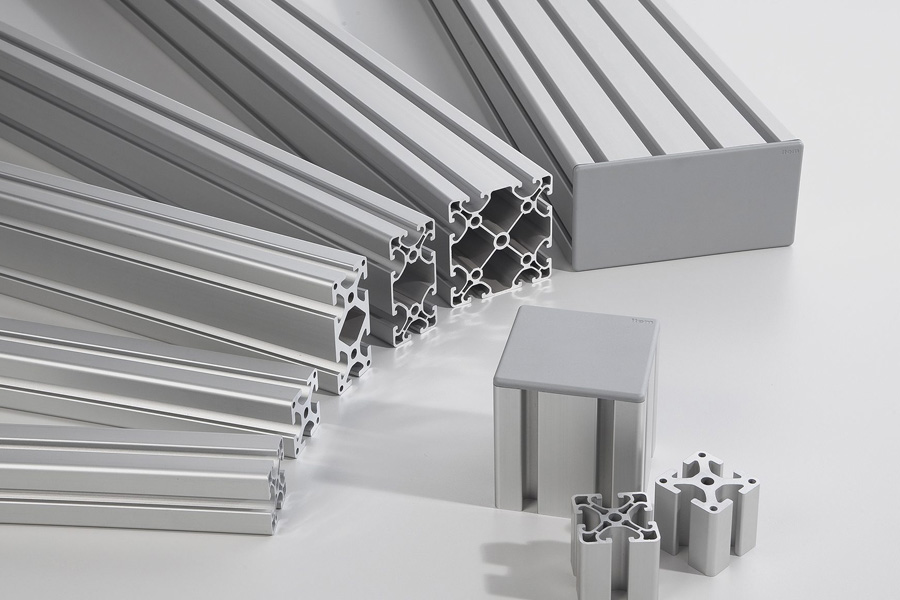

Aluminium profiles and components are being increasingly recognized not for their strength and versatility but also for the positive impact they have on sustainability across various industries. With the growing focus on issues influencing global practices, it is crucial to grasp the eco-friendly advantages and recycling methods associated with aluminium profiles. This piece delves into how aluminium profiles contribute to efforts and provides guidance on effectively recycling these valuable materials.

Environmental Advantages of Aluminium Profiles

Aluminium profiles offer a range of eco benefits throughout their lifespan.

1. Efficient Use of Resources:

Aluminium is a material found in nature that can be recycled extensively making it an environmentally sound choice for construction, transportation and consumer products. The recycling process uses less energy compared to producing primary aluminium helping conserve natural resources.

2. Strength and Longevity:

Known for their durability and resistance to corrosion aluminium profiles have a lifespan that reduces the need for frequent replacements. This longevity minimizes waste generation. Lessens the environmental impact associated with disposal.

3. Energy Conservation:

The lightweight nature of aluminium leads to energy savings in transportation and construction sectors. Reduced vehicle weight enhances fuel efficiency. Decreases greenhouse gas emissions, while lightweight building structures require less energy, for heating and cooling.

4. Recyclability:

Aluminium profiles have the advantage of being multiple times without compromising quality. The process of recycling aluminium consumes 5{7cbcebde640dca1332c17d5773acb3d77494c57b6daa80f60da1c3f4a8357df8} of the energy needed for its initial production making it an exceptionally energy efficient material to recycle.

Practices for Recycling Aluminium Profiles

Efficient recycling methods play a role in maintaining the value and environmental advantages of aluminium profiles.

1. Collection and Sorting:

Establishing systems for collecting scrap aluminium profiles from various sources like manufacturing facilities, construction sites and end of life products is essential. Sorting these materials ensures that different alloys and contaminants are separated, enhancing the efficiency of the recycling process.

2. Processing and Melting:

Scrap aluminium profiles undergo shredding, melting and refining processes to eliminate impurities and separate alloys. The molten aluminium is then shaped into ingots or billets for reuse in manufacturing profiles or other aluminium goods.

3. Closed Loop Recycling:

Encouraging closed loop recycling practices involves reintegrating recycled aluminium profiles into the production of profiles or components. This approach reduces the need, for aluminium while minimizing waste generation.

4. Environmental Impact Mitigation:

Implementing recycling programs helps reduce the repercussions linked to aluminium extraction and processing activities. Recycling conserves materials decreases energy usage and lowers greenhouse gas emissions compared to traditional production methods.

In this conversation about the sustainability of aluminium profiles we emphasize the advantages and recycling practices associated with using aluminium components. Industries can make an impact on resource conservation and environmental protection by focusing on recycling and recognizing the eco-friendly nature of aluminium.

To sum up aluminium profiles are crucial for sustainable development efforts. Their ability to be recycled durability and energy efficiency make them a top choice, for friendly projects. By promoting recycling methods and taking advantage of the eco-friendly features of aluminium profiles industries can contribute to a more sustainable future while meeting current construction and manufacturing demands.

When you opt for aluminium profiles you’re not just selecting a material – you’re choosing sustainability, longevity and a dedication to safeguarding our planet for generations to come.